Infant formula: It’s been around a lot longer than you may realise.

It was 1865 when German Chemist Justus von Liebig created and patented one of the first versions of baby formula.

Initially made in liquid form, it consisted of cow’s milk, wheat, malt flour and potassium bicarbonate.

Then in 1915, he developed a powdered form, allowing it to keep for longer.

Today, infant formula remains one of the most challenging sectors for food technology, contaminant testing and product quality.

The potential effect of contaminants and/or quality issues are magnified substantially by a baby’s small body mass, so the margin for error is (literally) microscopic.

Infant formula seeks to mimic the qualities of breast milk as closely as possible, and an important aspect of this is matching the overall fatty acid composition and other product characteristics.

As a key component, our specialised INFALAC oil blends used in infant formula contribute to achieving the desired nutritional benefits.

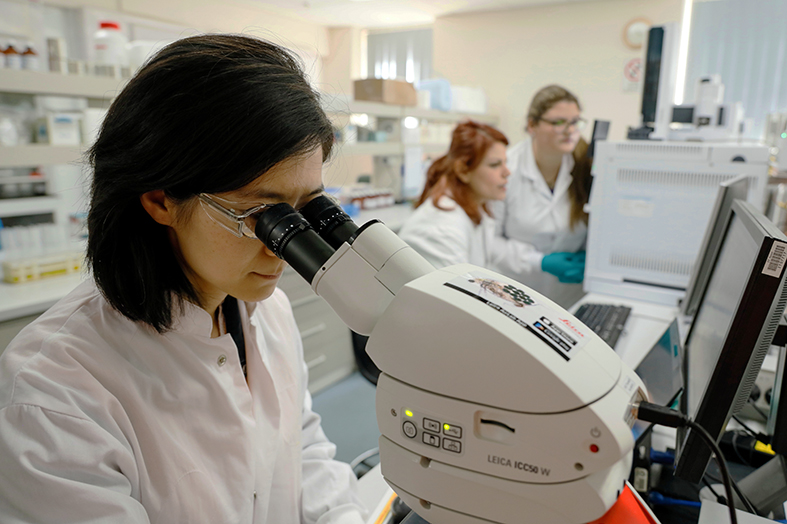

GrainCorp Foods’ processes and expertise in tailoring specific edible oil components to meet nutritional and immunological standards involves extensive research and testing – and the application of more than 20 years’ experience.

“No single individual oil blend will suit all infants, which is why we carefully select the raw materials required to meet certain fatty acid requirements.”

Peter Lymberis, Quality and Innovation Manager, GrainCorp Foods

“For example, some formulas will meet a certain level of Omega 3 and 6, while other specialised formulas contain the OPO fat structure found in breast milk, enabling easy digestion and optimising the uptake of essential nutrients.”

Typical oils used in infant formula include soyabean, non-GM canola, sunflower, coconut and specific concentrated oils such as Medium Chain Triglyceride (MCT) or 1,3 Dioleoyl-2-Palmitoyl glycerol (OPO).

At our West Footscray facility, in Victoria, our highly advanced Gas Chromatography/Mass Spectrometry machine delivers a significant quality and food safety advantage.

With this capability, we are one of only a few companies in the region with the capacity to perform sophisticated contaminant testing, including 3MCPD and GE levels.

In addition to testing for customers, we also collaborate on research and co-development programs with universities and industrial research organisations.

All of which makes it possible for us to play an integral role in providing infant nutrition.